In the rapidly evolving world of technology, cellphone manufacturing stands out as a sector profoundly shaped by industrial automation. The integration of advanced automation technologies, including the use of servo drives, has revolutionized the production process, enabling manufacturers to meet the increasing consumer demand for high-quality, innovative mobile devices.

This article explores the role of industrial automation in cellphone manufacturing, detailing each stage of the production process and highlighting how automation enhances efficiency and precision.

Overview of Cellphone Manufacturing

Cellphone manufacturing is a complex, multi-step process that requires precision and scalability. From the initial design and material procurement to assembly and quality control, each phase needs to be meticulously managed to ensure the final product meets rigorous standards of functionality and design.

Automation plays a crucial role in this process, not only to enhance precision but also to streamline operations and reduce costs.

Key Stages of Automated Cellphone Manufacturing

1. Design and Prototyping

The process begins in the design phase, where software tools are used to create digital models of the cellphone. Automation in prototyping, including CNC machining and 3D printing, allows for rapid production of prototypes to test for design viability and function.

2. Material Preparation and Component Manufacturing

Automation is critical in the material preparation phase, where various components like chips, circuit boards, and the metal and plastic parts of the phone’s body are manufactured.

Precision is paramount, especially when creating the motherboard and other electronic components that involve intricate patterns and structures.

Here, servo drives are crucial as they control the machinery that etches, cuts, and assembles these delicate parts with high precision.

3. Assembly

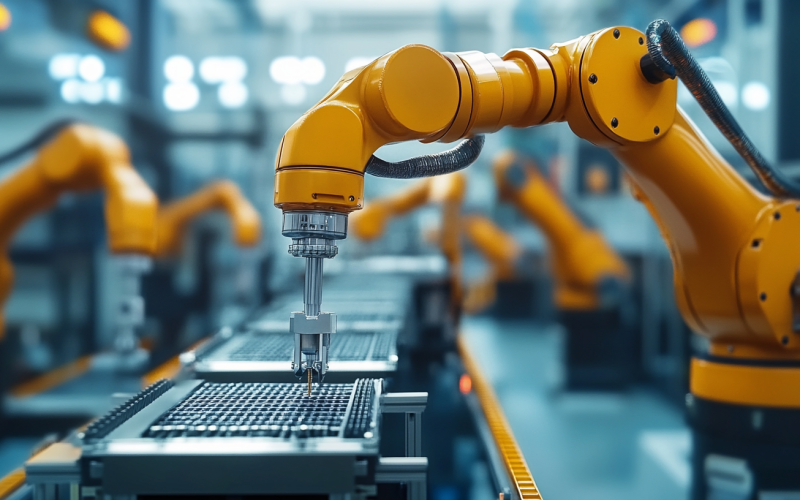

This stage is where the bulk of automation is visible. Robotic arms equipped with servo drives perform a variety of tasks such as placing and soldering components on the circuit board, assembling the screen, and screwing the body parts together.

The precision and speed provided by servo-driven robots are vital for maintaining the pace required to fulfill large orders typical in the cellphone industry.

4. Testing and Quality Control

After assembly, every device undergoes a series of automated tests to ensure functionality and performance. These tests might include software simulations, camera tests, battery checks, and stress tests to simulate real-world use conditions.

Automation ensures that these tests are thorough and consistent, minimizing the likelihood of defective products reaching the market.

5. Packaging

The final step in the manufacturing process is packaging, which is also automated. Machines precisely fold boxes, insert the phones along with accessories like chargers and earphones, and seal the packages. This phase ensures that the product reaches the consumer in pristine condition, enhancing user satisfaction.

Benefits of Automation in Cellphone Manufacturing

1. Enhanced Efficiency and Productivity

Automation significantly speeds up the production process, allowing for higher throughput. This is essential in an industry characterized by high consumer demand and frequent updates to device models.

2. Superior Quality and Consistency

Automated processes ensure that each component and each phone are built to the same specifications, reducing variability that can affect the user experience. Servo drives such as the DDS02.1-A050-D contribute to this consistency by enabling precise movements during component placement and assembly.

3. Reduced Costs

Though the initial investment in automated systems can be high, the long-term savings are substantial. Automation reduces labor costs and increases output, allowing companies to scale production without a corresponding increase in errors or defects.

4. Improved Worker Safety

By automating potentially hazardous tasks such as component soldering or extensive repetitive tasks, the risk of workplace injuries is significantly lowered. This not only enhances safety but also improves overall workplace morale.

Challenges and Future Directions

The integration of automation into cellphone manufacturing does pose challenges, including the need for high capital investment and ongoing maintenance costs. Additionally, as technology evolves, keeping up with the latest advancements in automation can be both costly and technically demanding.

Looking ahead, the trend in cellphone manufacturing is moving towards even greater automation. The future may see the integration of AI and machine learning to further optimize production processes and adaptive manufacturing techniques that can seamlessly switch between different product models without significant downtime.

Conclusion

Industrial automation has established itself as a cornerstone of modern cellphone manufacturing, with servo drives playing a pivotal role in ensuring the precision and efficiency of production. As technology continues to advance, the extent and sophistication of automation will likely increase, pushing the boundaries of what can be achieved in manufacturing high-quality cellphones efficiently and at scale.